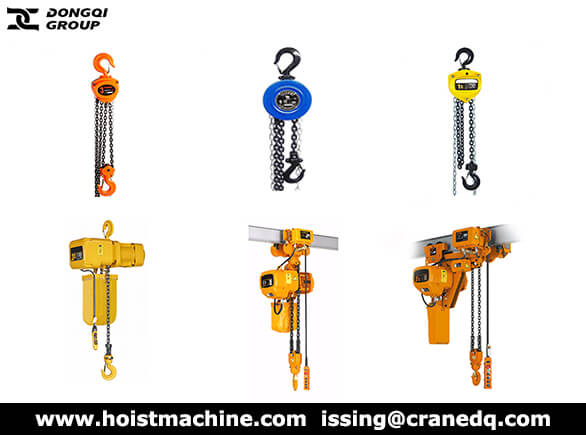

Electric chain hoists are used in manufacturing, maintenance and in distribution to transport materials. Chain hoists are available with top hook suspensions, hand push trolleys and motor driven trolleys. Dongqi Hoist Machine can offer you with a variety of chain hoist models and options to choose from.

Electric Chain Hoist or Wire Rope Hoist?

- Electricity is almost universally available and inexpensive.

- Productivity, ergonomics, and safety are enhanced.

- They are normally smaller and more compact than wire rope hoists, as a drum is not required to store wire rope.

- Overload clutch to prevent dangerous overloads is normally standard.

- Portability is excellent as standard hook mounting allows simplified installation (Lug mount required on wire rope hoist to wrap rope on drum precisely).

- Lift can be changed at any time with minimal cost by simply changing chain length.

- Numerous configurations and speeds are available in lighter capacities.

- Chain tends to be a more durable lifting medium than wire rope.

- Headroom of chain hoists is often better.

- Chain hoists are normally less expensive than wire rope.

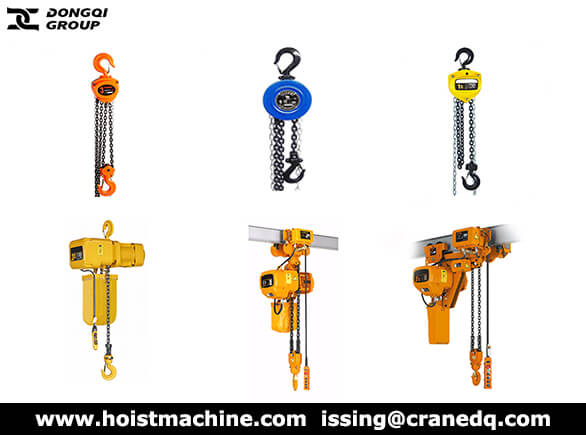

Electric Chain Hoist and Wire Rope Hoist

Manual Chain Hoist or Electric Chain Hoist?

- When workstations require a chain hoist lifting system, there are two primary categories of hoists that purchasers can choose from–manual chain hoists and electric chain hoists.

- Manual chain hoists typically serve maintenance applications and other light duty service assignments. Manual chain hoists range from 100KG capacity to 32 tons. For tight spaces and light duty applications, manual lever pullers serve as a compact, lightweight alternative to manual chain hoists.

- Electric chain hoists serve light capacity applications that require more repetitive lifting. They typically are used with jib cranes, monorails and workstations. Electric chain hoists are available in a variety of speeds, from single speed for lower duty pick and place operations, to two-speed for greater control, on up to inverter controls that offer smooth operation along a wide range of variable speeds.

- Electric chain hoists with variable frequency drives provide smooth starts and stops of the trolley and hoist motions, which reduces wear and mechanical stress by minimizing load sway. The wider range of speed control also permits more accurate and precise load positioning.

Manual Chain Hoist and Electric Chain Hoist

How to Select Your Right Chain Hoist:

- Capacity: You need to know the maximum weights of the loads you intend to lift.

- Lift: You need to determine the amount of chain lift (or length of chain) for your hoist.

- Lifting Speed: The load being lifted, if the load fragile, the surrounding environment, and hazardous conditions or environments, and is there adequate spacing around to pick and place the loads safely.

- Voltage & Power: You need to determine the voltage of your power source. By choosing the wrong voltage can instantly damage your new hoist, not covered by warranty.

- Pendant Control Cable Length: Special lengths for pendant cable drop can be configured to meet specific needs as well.

- Trolley:

- Plain Trolley: A plain/push is operated by maneuvering the trolley along the Beam by human power via the hoist operator. The operator will grab either the hook or the item being lifted and pull or push the item to move it in the desired direction along the Beam.

- Geared Trolley: A geared trolley is used by pulling a chain hanging from the trolley to maneuver the hoist along the beam or track. A geared trolley operated by pulling the hand chain.

- Motorized Trolley: The motorized trolley option has motor attached to the side of the trolley wheels, and usually has its own control pendant. A trolley speed must be specified when ordering a motorized trolley.

- I Beam Flange Width: I-Beam: An I-beam, also known as H-beam, W-beam or WF-beam (for “wide flange”), is a beam with an I- or H-shaped cross-section.

Electric chain hoists selection guide

How to Buy Electric Chain Hoist?

Items to consider when selecting a chain hoist:

- Type: Fixed type or manual trolley or electric trolley?

- Lifting capacity: ? ton

- Power supply: 220V-440V, 50/60Hz, single or three-phase? (Customized)

- Lifting height: ? m

- Lifting speed: ? m/min

- Application: What materials to be lifted?

If you’re not certain what types of chain hoists are best for your applications, contact us now to discuss your requirement.