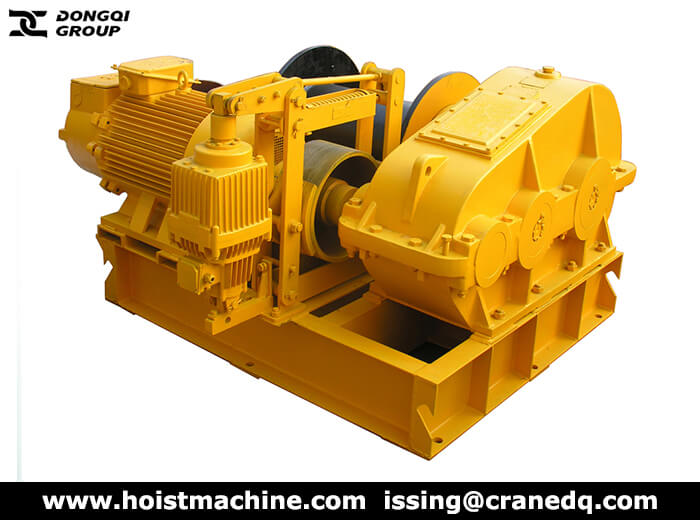

Industrial Electric Winch for Sale

Dongqi industrial electric winch is driven by the motor. It is widely used because of its simple operation, large amount of rope and convenient displacement. It is mainly used in building, hydraulic engineering, forestry, mining, wharf, etc.

Industrial electric winch for sale

Industrial Electric Winch Parameter:

- Loading capacity: 1-200 ton

- Volts: 12v-240v

- Wire rope capacity: 20-3600 m

- Working speed: 5-35 m/min

- Power supply: 50/60HZ, 3Phase

- Customized according to your requirements.

Features of Industrial Electric Winch:

- Industrial heavy duty winch can offer heavy lifting and puling force and different capacity as needed.

- Heavy-duty, industrial contactor control pack is sealed and weather resistant.

- Mechanically locked clutch allows freespooling of winch rope.

- Heavy-duty 12V or 24V series wound motor.

- Automatic, self-locking disc brake. Highly reliable and robust.

- Large 4 inch drum diameter for longer winch rope life with less kinking.

- Hardened steel, 3-stage planetary geartrain for efficient and reliable operation.

- Weather-proof Industrial quality remote with 10m twist-on connector.

- Compact structure and reasonable design.

- Construction winch is easy to install, operate and maintain.

- Industrial electric winch works reliably with low noise.

Built to Specifications:

- All winches are load tested and certified prior to shipment.

- Pendant: Various button configurations available for pendants and remote controls.

- Controls: Single and two-speed control packages available with a standard reversing starter or choose variable speed winch operation with an AC inverter or vector drive. Weather resistant, marine grade and explosion-proof enclosures are available.

- Gearing: 100% Sealed gearing with oil bath lubrication unless otherwise specified. Right angle, in-line and planetary gear sets accommodate all reduction and space limitation requirements.

- Wire Rope: Available upon request, wire rope is sized for winch capacity and application.

- Motor Brake: Provided unless otherwise specified to hold suspended or unstable loads.

- Cable Drum: Sized to meet loading, cable, fleet angle and space restriction requirements.

- Motor: Electric motor properly sized for starting and running loads and configured for environmental conditions.

- Bearings: Precision self-aligning pillow block or flange cartridge bearings with grease fittings.

- Mountings: Space-saving frame layouts may be sized to match existing mounting requirements.

- Fittings: Swivel hooks, blocks, clevis fittings and other rope attachments are available.

- Spooling Aids: Pressure rollers, fairleads, level winds and sheaves available for cable control.

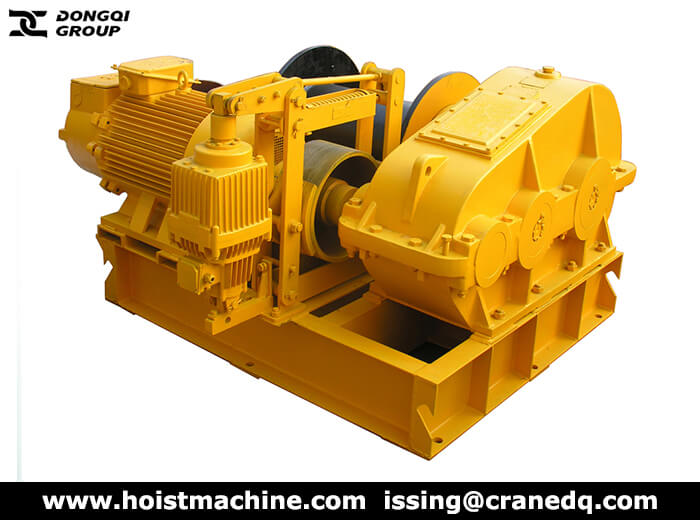

Industrial heavy duty winch for sale

Maintenance Method of Industrial Electric Winch:

- The environment should be kept dry frequently, and the surface of the motor should be kept clean. The inlet should not be blocked by dust or fiber.

- When the motor’s thermal protection occurs continuously, it should be found out that the fault comes from the motor or the overload or protection device setting value is too low, and after the fault is eliminated, the operation can be put into operation.

- The motor should be well lubricated during operation. The general electric motor runs about 5000 hours, namely should replenish or replace the grease, when the bearing is overheated or lubricated, the hydraulic pressure changes the grease in time.

- Replacing grease, should clean up the old oil, and gasoline wash oil bearing and the bearing cover, then put the ZL – 3 lithium base grease filling bearing between the inner and outer ring cavity 1/2 (2) and two-thirds (4, 6, 8).

- When the life of the bearing is finished, the vibration and noise of the motor will increase significantly. When the radial clearance of the bearing reaches the following value, the bearing shall be replaced.

- When the motor is removed, the rotor can be removed from either the shaft or the non-extension end.

- If it is not necessary to remove the fan, it is more convenient to remove the rotor from the non-shaft end. When the rotor is drawn out of the stater, it should be prevented from damaging the stater winding or insulation.

- Replacing winding must take note of the original winding form, size and number of turns, wire gauge, etc., when the data lost, should be to the factory, change the original design winding, often worsen or a few of the motor performance, even not be able to use.

Safe Operation of Industrial Electric Winch:

- Before operation, check the anchor of the hoisting machine, whether the loading rack is firm, and check whether the clutch and brake are sensitive and reliable. Exposed belt, gear and other transmission devices, whether the protective cover is complete.

- The wire rope should be arranged neatly. In the process of lifting the crane, at least 3~5 laps should be kept on the drum, and the wear degree of the wire rope should not exceed 10%, and the steel wire rope of the pulley can’t be connected.

- The winch should be used and maintained by special people, and check whether the grounding circuit is in good condition. If the electrical equipment is found to be leaking or other faults, it should report to the fore in time. No unauthorized repair.

- The hoisting basket must be equipped with a safety door, which can only lift the material and strictly prohibit carrying people. The crane stays in the air, except for the brake, and also with a parking rack. It is strictly forbidden to walk under the crane on the wire rope.

- The loading rack must have good grounding and lightning protection devices. Check whether the limiter is flexible and reliable once a week. It is strictly forbidden to transport overweight or long articles.

- Power supply should be cut off when there is a power failure in the operation. Lowered the object or crane to the ground.

After the operation is completed, the hoisting of the crane or object should be lowered to the ground, and the power supply should be cut off and the switch box should be locked.

Dongqi has produced and customized winch machines for a long time and has clients all over the world. No matter you want to select small one or to buy huge one, you can just get the right and quality one with very reasonable price. Welcome to contact us now: issing@cranedq.com!